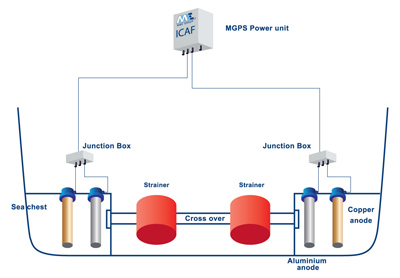

Marine growth in sea chests, box coolers and seawater piping systems is a potential threat for the performance and condition of your ship or installation. Blockages caused by barnacles and mussels are expensive and time consuming to remove and can have serious consequences. Engines can run at abnormally high temperatures, resulting in unnecessary increased fuel consumption and lower performance. To combat this risk, the MME MGPS was developed. Once installed it provides low maintenance and continuous (dual) protection against most hard and soft foulings as well as corrosion.

The MME MGPS utilizes an impressed current, employing sacrificial cu+al anodes and steel cathodes, and consists ofspecially alloyed anodes which are connected electrically to a digital controller. The system generates copper ions by electrolysis in seawater which flow through the system creating an environment which prevents micro-organisms to settle. Aluminium anodes control corrosion of sea chests, box coolers and piping systems. Ferro anodes are used for CuNi pipe work. Anodes are replaced during dry-docking or, depending on the design, whilst the vessel is afloat.

The effectiveness of the fouling prevention mainly depends upon the conditions of the water and its flow. Because the latest MME MGPS can communicate with pumps, PC and Vessel Management Systems, it offers an intelligent solution for fouling and corrosion problems that occur in (cooling) water systems. By constantly monitoring the flow rate and conditions, the MME system always offers optimal protection.

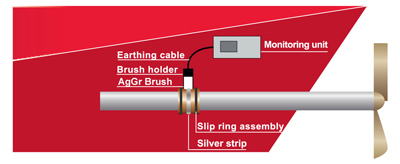

The shaft grounding drains any current sent out by the ICCP system and/or the sacrificial anodes which may enter into the propeller shaft via the propeller.

If undrained, the potential difference between the shaft grounding and the hull may cause stray currents in the propeller shaft bearings or gearboxes, which could lead to corrosion and subsequent prematureA failure. Generally each propeller shaft must be fitted with a grounding system.

The system consists of a set of silver graphite brushes sliding over a copper slipring incorporated with a silver strip. The silver brushes are pressed on the silver strip to ensure maximum contact with the least resistance and allow for optimal drainage of the current.

The prevention and monitoring of corrosion on the underwater hulls of ships and marine structures are part of the core competences of the MME Group. For this we offer intelligent solutions and supply fully digital Impressed Current Cathodic Protection Systems (ICCP) with high class monitoring options. This system consists essentially of several Impressed Current Anodes, Reference Cells and a Power Controller Unit.

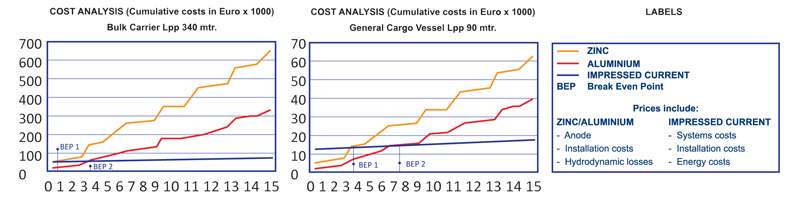

Hull corrosion has posed a problem to ships for many years. Of all the various corrosion protection systems used by the shipbuilding industry, ICCP is the most efficient with contact and monitoring solution, and on the longer run also cost effective.

A recent developments is the high frequency controlled ICCP electric power units. The use of big and expensive tranformers is not required anymore. Hence, much smaller and lighter power control boxes can be offered at a even more competitive prices.

The main advantages of ICCP are both technical and commercial.