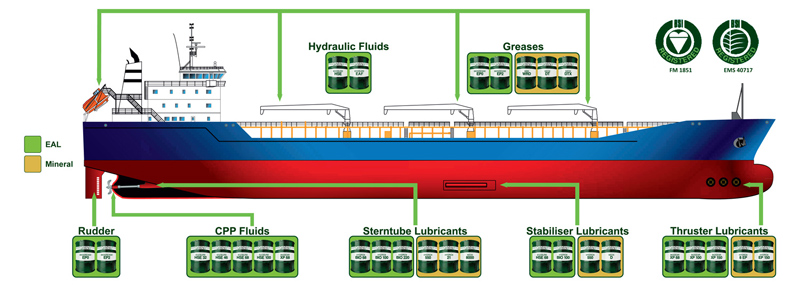

The Vickers Oils range of VGP compliant environmentally acceptable lubricants (EALs) have been approved by various OEMs for use in controllable pitch propellers (CPPs) where there is potential for fluid loss to the environment to occur.

The products provide excellent equipment protection, superior thermal stability, exceptional oxidation resistance and good antiwear performance under severe conditions.

Vickers Oils also has a range of high performance, anti-wear hydraulic fluids which use state-of-the-art ashless zinc-free technology. ECOSURE exceeds the requirements of ISO 15380, which specifies the requirements for environmentally acceptable hydraulic fluids.

These products demonstrate performance superior to many mineral oil based fluids and competing biodegradable hydraulic fluids.

Vickers Oils has a range of environmentally acceptable lubricants (EALs) Since 2002 and mineral oil based lubricants designed to provide excellent lubrication of the sterntube bearings.

HYDROX BIO is an environmentally acceptable lubricant (EAL) range based on synthetic esters which meets the detailed ecological definitions and requirements laid down in Vessel General Permit (VGP). The HYDROX and NEOX ranges of mineral based sterntube lubricants provide excellent wear and corrosion protection.

HYDROX BIO 68, 100 and 150 (EAL) and HYDROX 550 (mineral) are the viscosity grades generally recommended by bearing and seal manufacturers for regular running in the sterntube.

HYDROX BIO 220 (EAL) and HYDROX 21 (mineral) are recommended for use particularly where problems of oil leakage past the aft seals is being experienced. In the majority of cases a significant reduction in leakage rate can be achieved.

The Vickers Oils range of environmentally acceptable lubricants (EALs) for this application are based on fully saturated synthetic esters and meet the detailed ecological definitions and requirements laid down in Vessel General Permit (VGP).

BIOGEAR XP is a range of Environmentally Acceptable Thruster Lubricants delivering superior anti-wear, EP and oxidation protection even under severe conditions. They meet the requirements of DIN 51517.

Vickers' range of mineral based thruster lubricants, HYDROX 8 EP and HYDROX EP 150 are extreme pressure (EP) gear lubricants. They provide a very high standard of anti-wear performance suitable for the lubrication of heavily loaded gears, giving high resistance to micropitting and scuffing.

They have been formulated to be suitable even for applications where a combined gear and hydraulic function is required. Stable emulsions are formed with any water that may enter the unit and so provide protection against corrosion.

BIOGREASE EP is an environmentally acceptable lubricant (EAL), based on fully saturated synthetic esters and meets the detailed ecological definitions and requirements laid down in Vessel General Permit (VGP). BIOGREASE EP offers improved operation and lower environmental risk leading to overall cost savings.

BIOGREASE EP2 and BIOGREASE EP0 are Lithium/Calcium thickened greases. They provide excellent corrosion protection and resistance to wash off from rain and seawater and can be used on deck equipment, wire ropes and as rudder stock lubricants. BIOGREASE EP0 has been specifically formulated for use in rudder stocks as recommended by certain OEMs.

Vickers Oils also have a range of mineral based greases which deliver a high standard of lubrication and corrosion protection. NEOX DT and NEOX DTX have the consistency of soft grease. Both products are recommended for use on wire ropes and rigging, container lashings, hatch cover bearings and runners, deck winches and slipway rails. Unlike many conventional types of grease, these products do not harden excessively or crack when subjected to cold, wet conditions.