Established since 1980 in Spain, PETER TABOADA® is specialised in the design, manufacturing and marketing with its own technology of water treatment and purification systems for the marine, industry.

The PETSEA RO Reverse Osmosis systems are designed to produce high quality purified or ultra pure water. They are built to convert sea water to fresh water in the most rigorous operation conditions. Working continuously in marine environment, it produces highest water quality standards either for crew consumption or other uses.

The PETSEA RO systems are expandable and highly versatile being manufactured to each specific need. They have pumps and hydraulic equipment that permit the installation of extra membranes to increase the water production without lowering the performance to the system.

PETER TABOADA has the widest range of RO plants,from 0.5 TPD to 20 TPD (SW-Y Series) and from 30 TPD to 120 TPD (SW Series).

| PETSEA R/O SW-Y SERIES |

PRODUCTION | POWER aprox. |

DRY WEIGHT aprox. |

| 5/6 10/12 |

0.5/0.6 m3/day 1/1.2 m3/day |

2kW | 50Kg |

| 10/18 20/34 30/52 |

1/1.8 m3/day 2/3.4 m3/day 3/5.2 m3/day |

2.2kW | 64Kg |

| 40/50 60/80 |

4/5 m3/day 6/8 m3/day |

3.0kW | 100Kg |

| 40/55 80/90 110/120 130/150 |

4.5/5.5 m3/day 8/9 m3/day 11/12 m3/day 13/15 m3/day |

5.5kW | 150Kg |

| 200 | 20 m3/day | 7.5kW | 180Kg |

Production Calculated on 38.000 PPM Salinity, 18/25ºC, 65 bar

| PETSEA R/O SW-Y SERIES |

PRODUCTION | POWER aprox. |

DRY WEIGHT aprox. |

| 300 400 500 600 |

30 m3/day 40 m3/day 50 m3/day 60 m3/day |

15/17,2 kW | 1.050 Kg 1.220 Kg 1.540 Kg 1.640 Kg |

| 800 | 80 m3/day | 22/25 kW | 1.735 Kg |

| 1000 | 100 m3/day | 30/34,5 kW | 1.900 Kg |

| 1200 | 120 m3/day | 55/63 kW | 2.200 Kg |

Production Calculated on 38.000 PPM Salinity, 18/25ºC, 65 bar

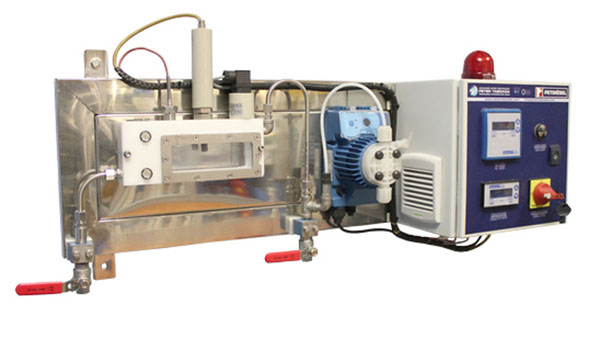

The diesel engine cooling water quality control system PETDIÉSEL is the first system developed for providing the most suitable solutions for both control and maintenance of the diesel engines circuits. Totally designed and built by PETER TABOADA, PETDIÉSEL system controls and protects the cooling circuit applying the highest technology.

The system controls the water pH of the cooling circuit by an automatic system: by means of continuous measuring and chemical dosing, pH is kept between 7.8 to 8 at temperatures of 70ºC to 90ºC. The result is corrosion instantly avoided and rust and mud grown is reduced to minimum, which increases the cooling power of water.

The water conductivity is controlled by another automatic system which continuously measures the quality of water in the circuit and informs by an acoustic and visual alarm if the conductivity is not suitable (casual contamination produced by seawater from the refrigerator)

The Oil model includes a probe for measuring hydrocarbons. The Oil-T model includes probes for measuring hydrocarbons and sludge in water.as well as the standard model, the system tells by an acoustic or visual alarm when the measured value is over the set by the user.

The models PETDIESEL PLUS® also include a water demineralizer also with automatic performance which produces and inject purified water in the compensating tank when it is needed. By this way it is assured that the water in the cooling circuit is of suitable quality.

The amortization of PETDIESEL® and PETDIESEL PLUS® is quick, avoiding the wearing away of main devices of the engine and making a great save.